Direct vs. Indirect Materials in Procurement: What is More Challenging?

Let's look at the similarities, differences, and challenges between direct and indirect material procurement, and what that means for procurement professionals.

Isn't it all just 'companies buying stuff'?

To most people outside the world of procurement, there is no difference between direct materials and indirect materials, or the procurement process involved in each. To them, its all the same — companies buying 'stuff' from outside vendors.

But for those working daily in the fields of procurement, purchasing, or supply-chain management, there is indeed quite a difference — not only in the materials being purchased themselves, but in the actual procurement processes, tools, challenges, and people involved.

Let's take a look at the differences of direct vs. indirect materials and the challenges involved with each, and why it matters.

Direct vs. Indirect: The definitions

Generally speaking, the split between direct vs. indirect materials depends on whether the material is part of the Bill of Materials (BOM) for a product a company sells.

Direct materials are part of the BOM, integrated in the final product both physically and from a cost standpoint. They directly add to the Cost of Goods Sold (COGS) for a product, and the consumption of direct materials is directly linear with how much product a company produces and sells.

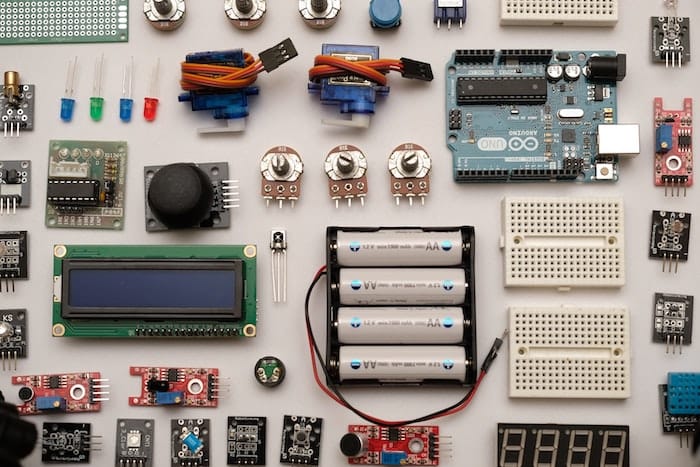

Examples include circuit boards inside electronics, door handles for cars, or the fuel pump inside SpaceX's Merlin rocket engine.

Indirect materials, on the other hand, are other things a company needs to either produce a product, design or create a product, or generally support the business, but not things that go into the product themselves.

To put it simply, these materials are the overhead for a business, the cost and use of which is not directly attributable a unit of product the company sells — hence the 'indirect' terminology.

Indirect materials may still be rolled up into COGS from an accounting standpoint, and may even be related to production, but they are not actual components of the final product.

Examples of indirect spend includes office supplies, professional services (legal, consulting, etc.), IT equipment, travel costs, and just about everything else needed to keep a company running.

Certainly both direct and indirect materials, and therefore direct and indirect procurement, are critical for any business. After all, for many companies, including almost any company that sells physical products, external spending is (by far) their largest cost category — direct and indirect materials combined.

Direct vs. Indirect Procurement — The Similarities

Almost any purchasing decision, whether made by a company, or made by an individual deciding where to go for lunch, comes down to the same general factors — you want the best quality product or service, at the best price, on the right schedule and terms. It's not rocket science.

The world of B2B procurement is no different.

And in that sense, procurement of direct and indirect materials are very similar. Both share a common set of tasks and functions including:

- Working with colleagues to identify business requirements and document what needs to be purchased

- Outlining criteria for how a decision will be made, possibly with an objective scoring system

- Researching and evaluating suppliers

- Negotiating on pricing and commercial terms

- Building relationships with new and existing suppliers, and

- Making decisions in a rational and transparent manner

But often there are nuanced differences between how these things are done for indirect and direct materials, and even some larger differences to point out.

Direct vs. Indirect Procurement — The Differences

The biggest difference between direct and indirect material procurement often relates to the breadth and depth of specialization — specialization of the procurement organization and staff, as well as specialization of the tools and processes used.

Indirect Spend — Broad, Horizontal Focus

The range of indirect materials and overall indirect spend of a company is often very broad — a very large assortment of things are purchased, often highly commoditized products or services, and often on a rather intermittent basis.

For example, a company may have an IT support contract with an outside vendor that they renew on an annual basis.

In the months leading up to that contract renewal, there may be a lot of activity between the procurement team and that vendor discussing renewal terms and reviewing past performance.

But in the months in between, there may be very little activity with the procurement team themselves.

In the meantime, the procurement team is focused on other important things — negotating lower costs on office supplies, travel expenses, or even employee benefits.

Most companies are simply not big enough to have large central procurement teams filled with specialists in each of these areas. There is simply too much variety to cover.

Instead, most central procurement teams responsible for indirect spend have a horizontal focus, bringing best practices in the procurement process, negotiation, and supplier management to the internal teams they enable.

Direct Spend - Specialized, Vertical Focus

Direct material procurement, on the other hand, is often much more specialized in nature, and often requires a more technical and deeper focus on the actual materials being purchased and the suppliers involved.

The materials being purchased are integral parts of the company's products, and are therefore usually much more consistent over time.

A company typically doesn't make aircraft engines one day, then lamp shades the next day. (Except for maybe GE a few decades ago...)

This both allows and requires a direct material procurement team to become experts in specific areas of a supply chain with deep industry & commodity specialization.

Direct material procurement typically differs from indirect procurement in the following ways:

- Wider geographic supplier base — specialized component manufacturers spread across the world

- Specific technical requirements — specific manufacturing capabilities required by the supplier, detailed technical specifications for the materials themselves, and technical know-how from the procurement team in order to intelligently manage these technical details.

- Highly specific quality requirements — both on the part level (AQL, Cp/Cpk, etc.) and on the supplier level (ISO900x, Six Sigma, etc.)

- Detailed schedule requirements — evaluating and tracking component lead times, delivery dates, and other things critical to a company's own production schedule.

- Multiple source selection — choosing multiple 'winners' for a certain RFQ/RFP is common in direct material sourcing as a risk mitigation or price negotiation strategy, increasing the overall workload on the procurement team.

- More RFQs rather than RFPs — including complex multi-line RFQs for entire Bills of Material (BOM) — usually aided by sourcing automation software

- Different internal customers — direct-material procurement teams typically work closely with manufacturing, engineering, and product development teams, while indirect material procurement teams usually have to support all functions in a company.

- Irregular and short purchasing cycles — purchasing needs for direct materials often follow new product development schedules, and are often triggered by emergency situations like quality issues at existing suppliers, unexpected spikes in demand, and other unplanned events.

This is only a partial list. We've gone into more detail in a separate post here about the key things that set apart direct material procurement from indirect.

Needless to say, procurement of direct materials and indirect materials can be quite different. There is simply a different set of priorities, business needs, and overall role in a company for each of them.

Direct vs. Indirect Procurement — Which is more challenging?

Certainly there is no right answer here — both direct and indirect procurement have their own unique set of challenges, and they can differ greatly from industry to industry, and company to company.

Indirect-focused procurement teams have the unique challenge of managing an incredibly broad range of vendors, materials, services, and internal customers. And of course the never-ending challenge of getting their internal stakeholder colleagues to follow all of the well-justified purchasing policies, processes, and guidelines they have established.

Direct material procurement teams have a different set of challenges based on their different set of priorities and more specialized and vertical focus.

Both disciplines are rapidly evolving as businesses constantly try to streamline operations, embrace the globalization of supply chains, and stay ahead of competition.

For this reason, procurement teams, both indirect and direct, are turning to new technology-based solutions to help them stay ahead and scale their effectiveness.

'Strategic sourcing' platforms, digital procurement, e-procurement, and other buzzwordy solutions are commonly thrown around. But just like the differences in the direct vs. indirect disciplines themselves, the tools and solutions available can vary greatly.

Direct vs. Indirect — Different tools for different priorities

Sourcing automation, digital procurement, or other procurement automation solutions have been growing in popularity in the recent years. The reasons are obvious — the general process of 'companies buying stuff' is notoriously broken and inefficient, full of paperwork (the 'dead tree' kind), manual approvals (the 'wet-ink' kind), and lazy purchasing decisions made by overworked teams.

In my own experience, I have noticed that most of the early tech-based solutions coming on the market are primarily focused on indirect material procurement. Streamlining things like purchasing supplies, one-off IT equipment, and other 'overhead' items needed to keep the internal team of a company moving.

These solutions are often quite inward focused, with the main users being internal employees, central procurement teams, and admin staff. And there is certainly a lot of value there.

But these solutions are quite limited in their usefulness for managing direct spend and direct material suppliers.

Why? Because of the differences in priorities and focus as we've outlined above.

Direct material procurement typically involves a much longer and more involved engagement with a supplier, more of a focus on complex multi-line RFQs rather than more open-ended RFPs, more complex integrations with existing ERP, PLM, and/or QMS systems, complex dependencies on specific quality requirements, and a very high focus on schedules, lead-times, and technical requirements.

As with anything, tools are only helpful if you use the right tool for the right job.

Supplios — Purpose built for direct-material procurement

Building a modern sourcing automation and supplier engagement tool to help direct material procurement and supply-chain teams is the exact thing we set out to create at Supplios.

Purpose-built with these unique requirements in mind, we're bringing to life the exact tool that we wish we had ourselves when running complex global supply chains.

Supplios helps supply-chain and procurement teams lower their direct-material costs, increase their supplier base, and implement real strategic sourcing programs on more spend, all with less work.

If you, too, are on the direct-material side of the procurement world, we'd love to show you what we've built — we think you'll like it.

Drop us a line at hello@supplios.com or contact us and we'll setup a custom demo to show you how Supplios can save you and your team valuable time and scale out a world-class supply-chain.